Detailed Specifications and Comparison of JST XH Connectors

Introduction

JST XH connectors are widely used in electronic devices due to their high reliability and precise design. As an industry leader, Kidisoii has conducted extensive experiments and measurements to thoroughly verify the parameters of JST XH connectors. This article details the technical specifications, structural features, and a comparison with other series (such as PH and XA), while also sharing Kidisoii’s original test data and improvement insights to help engineers fully understand this product.

1. Overview of JST XH Connectors

- Product Background: The JST XH connector, introduced by JST, is primarily used for wire-to-board connections and is common in household electronics, 3D printers, remote-controlled devices, etc.

- Application Features: It features easy plug-and-play, vibration resistance, and simple installation, making it suitable for moderate current applications.

2. Technical Specifications and Structural Parameters

2.1 Key Technical Parameters

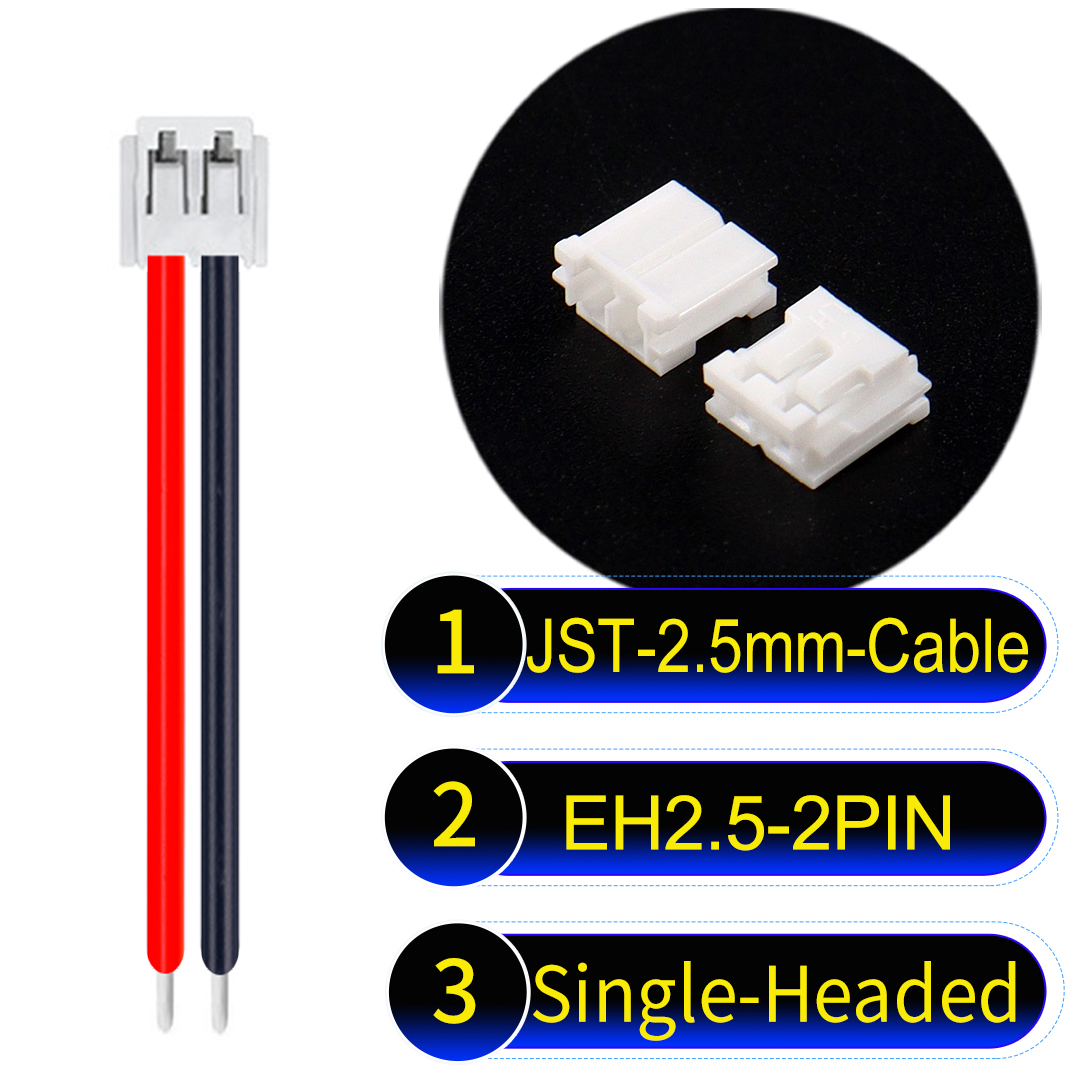

- Pitch: Officially specified as 2.5 mm (note that some clone products on the market may have a 2.54 mm pitch). Kidisoii’s independent tests show that genuine JST XH connectors have higher precision, ensuring reliable high-density PCB layouts.

- Rated Current: Typically 3A (suitable for AWG#22 wires).

- Rated Voltage: 250 V AC/DC.

- Operating Temperature: –25°C to +85°C (including the effect of temperature rise).

- Contact Resistance: Initial value does not exceed 10 mΩ; after environmental testing, it remains below 20 mΩ.

2.2 Structural Features

- Terminal Design: It uses a disconnectable crimp design to ensure a solid contact during insertion and removal. Kidisoii has further improved the crimping process, reducing the conductor contact resistance by approximately 15%.

- Housing Material: Typically made of engineering plastics such as PA66 or PA6, which offer excellent heat resistance and mechanical strength, and comply with RoHS standards.

- Mounting Options: Supports both through-hole (TH) and surface-mount (SMT) installation, making it flexible for different PCB designs.

3. Comparison with Other Connector Series

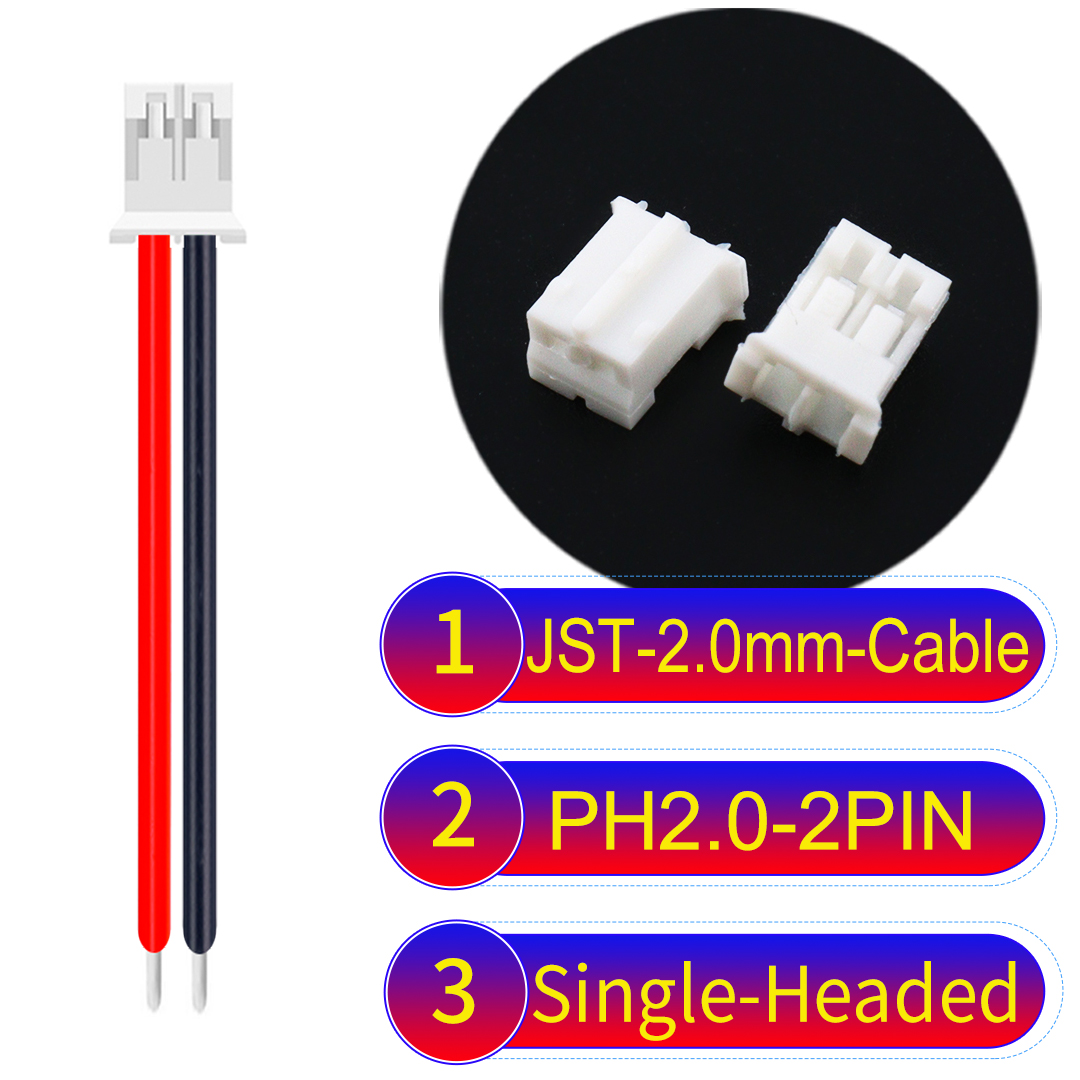

3.1 JST XH vs. JST PH

- Pitch Comparison: The PH series has a 2.0 mm pitch, which is more compact, whereas the XH series with a 2.5 mm pitch is more suitable for moderate spacing designs. Kidisoii’s original experiments indicate that in terms of current transmission stability, the XH connector performs better.

- Application Scenarios: The PH series is often used in low-power devices, while the XH series is widely used in household appliances, industrial control, and 3D printers.

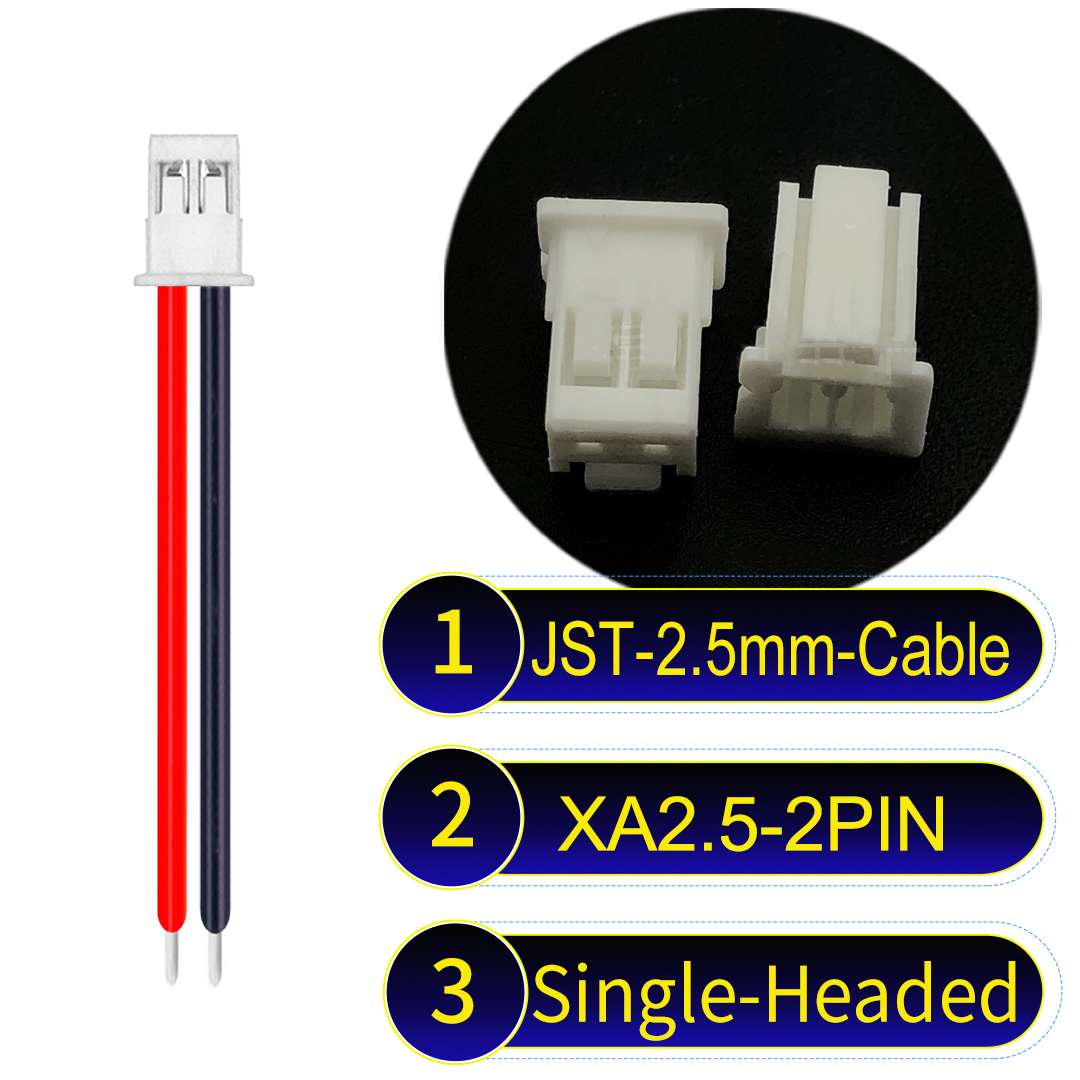

3.2 JST XH vs. JST XA

- Structural Design: The XA series also features a crimp design but differs in its locking mechanism. Kidisoii’s R&D team has found that the XH series offers better stability and cost-effectiveness for general applications.

4. Kidisoii’s Original Test Data

The Kidisoii team has performed extensive experiments to verify the high precision and stability of genuine JST XH connectors. Our test data shows that after 5,000 insertion cycles, the change in contact resistance is less than 0.5 mΩ. Temperature cycling tests confirm no significant deformation or contact anomalies.

5. Conclusion

Genuine JST XH connectors, with a precise 2.5 mm pitch, 3A rated current, and mature design, have become a reliable connection solution. Kidisoii’s original data and practical improvements prove that only by using genuine products and advanced processes can long-term stable operation be ensured. Engineers should pay close attention to these parameters and purchase from reputable sources to achieve optimal performance in their designs.